Model Name: Mechanical Pipette

Model No.: HiPette

Fully Autoclavable Mechanical Pipette

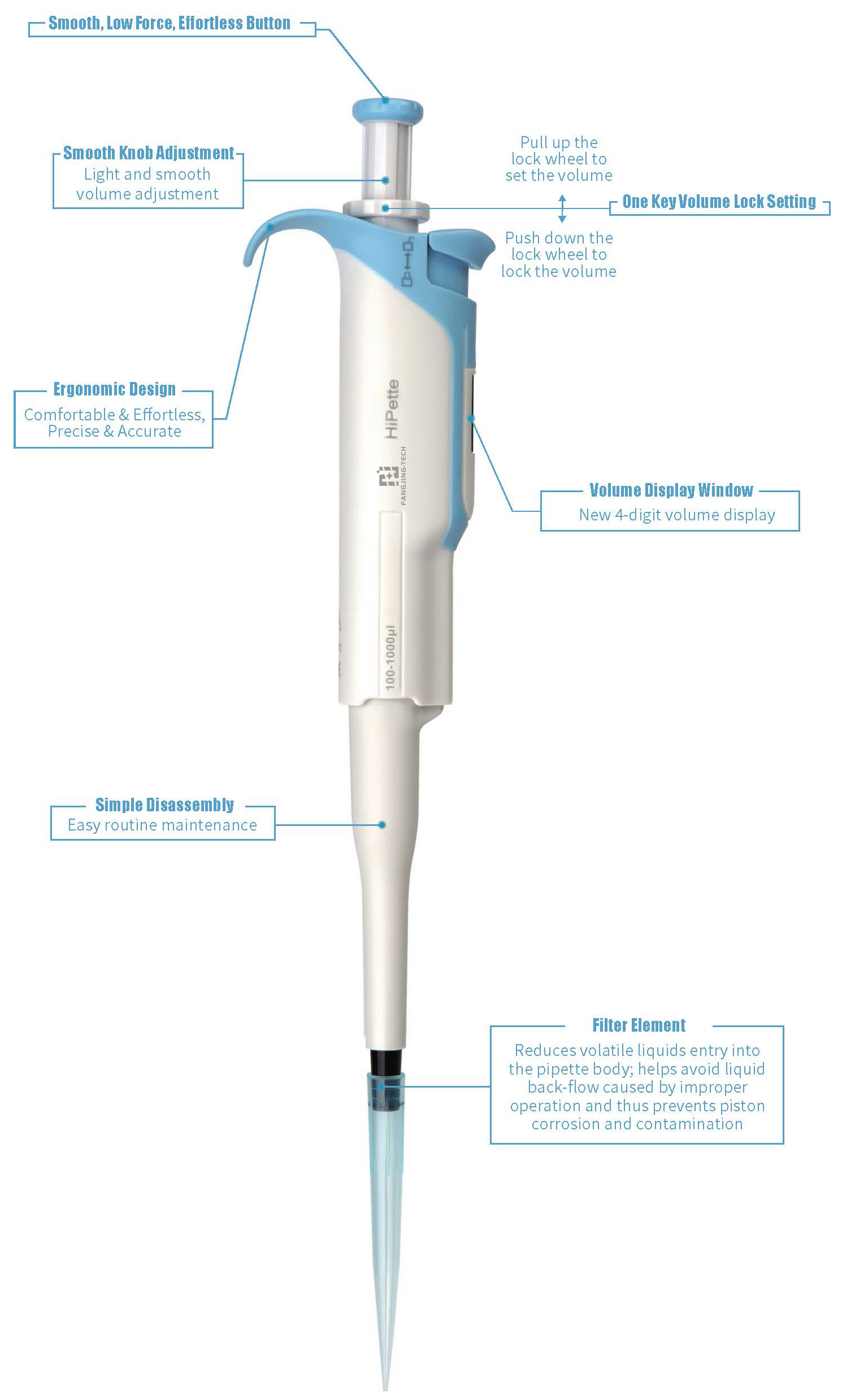

The Fangjing new generation full autoclavable mechanical pipette has the best ergonomic design and ultralight weight. It has been designed keeping in mind the human form and human factors to offer smooth and effortless ergonomic pipetting experience. It is UV sterilisable and resistant to strong chemical corrosion. In addition, the volume lock helps protect from volume changing accidentally, and achieve reliable pipetting of smallest volume of liquids.

Ultralight Ergonomic Design

Light weight and light pipetting force with soft range adjustment and piston movement offers effortless & fatigue-less pipetting experience.

Accurate Pipetting

Special material and the updated components & technologies effectively reduces the operating force for accuracy, precision and reliability.

Complete Sterilization

The best in class pipette material used is fully autoclavable. It gives better protection against chemical & physical corrosion, and offers enhanced UV resistance for higher durability.

Product Show

Specifications

Single Channel Adjustable Volume Pipettes (12 Models, Covering 0.1μL to 10mL).

Volume Range | Increment | Test Volume | Systematic Error | Random Error | ||

μL | μL | μL | μL | % | μL | % |

0.1 to 2.5 | 0.002 | 2.5 | ±0.04 | ±1.4 | ±0.02 | ±0.7 |

1.25 | ±0.03 | ±2.5 | ±0.02 | ±1.5 | ||

0.25 | ±0.03 | ±12.0 | ±0.02 | ±6.0 | ||

0.5 to 10 | 0.01 | 10 | ±0.10 | ±1.0 | ±0.04 | ±0.4 |

5 | ±0.08 | ±1.5 | ±0.04 | ±0.8 | ||

1 | ±0.03 | ±2.5 | ±0.02 | ±1.8 | ||

2 to 20 | 0.02 | 20 | ±0.20 | ±1.0 | ±0.06 | ±0.3 |

10 | ±0.12 | ±1.2 | ±0.06 | ±0.6 | ||

2 | ±0.10 | ±5.0 | ±0.03 | ±1.5 | ||

5 to 50 | 0.05 | 50 | ±0.45 | ±0.9 | ±0.15 | ±0.3 |

25 | ±0.35 | ±1.4 | ±0.20 | ±0.8 | ||

5 | ±0.15 | ±3.0 | ±0.08 | ±1.6 | ||

10 to 100 | 0.1 | 100 | ±0.80 | ±0.8 | ±0.20 | ±0.2 |

50 | ±0.50 | ±1.0 | ±0.15 | ±0.3 | ||

10 | ±0.30 | ±3.0 | ±0.10 | ±1.0 | ||

20 to 200 | 0.2 | 200 | ±1.20 | ±0.6 | ±0.40 | ±0.2 |

100 | ±1.00 | ±1.0 | ±0.30 | ±0.3 | ||

20 | ±0.50 | ±2.5 | ±0.14 | ±0.7 | ||

30 to 300 | 0.2 | 300 | ±1.80 | ±0.6 | ±0.60 | ±0.2 |

150 | ±1.50 | ±1.0 | ±0.45 | ±0.3 | ||

30 | ±0.75 | ±2.5 | ±0.21 | ±0.7 | ||

100 to 1000 | 1.0 | 1000 | ±6.00 | ±0.6 | ±2.00 | ±0.2 |

500 | ±5.00 | ±1.0 | ±1.00 | ±0.2 | ||

100 | ±3.00 | ±3.0 | ±0.60 | ±0.6 | ||

1000 to 5000 | 5.0 | 5000 | ±30.00 | ±0.6 | ±10.00 | ±0.2 |

2500 | ±15.00 | ±0.6 | ±7.50 | ±0.3 | ||

1000 | ±12.00 | ±1.2 | ±3.00 | ±0.3 | ||

500 to 5000 | 5.0 | 5000 | ±30.00 | ±0.6 | ±10.00 | ±0.2 |

2500 | ±15.00 | ±0.6 | ±7.50 | ±0.3 | ||

500 | ±12.00 | ±2.4 | ±3.00 | ±0.6 | ||

2000 to 10000 | 10.0 | 10000 | ±60.00 | ±0.6 | ±20.00 | ±0.2 |

5000 | ±40.00 | ±0.8 | ±10.00 | ±0.2 | ||

2000 | ±30.00 | ±1.5 | ±6.00 | ±0.3 | ||

1000 to 10000 | 10.0 | 10000 | ±60.00 | ±0.6 | ±20.00 | ±0.2 |

5000 | ±40.00 | ±0.8 | ±10.00 | ±0.2 | ||

1000 | ±30.00 | ±3.0 | ±6.00 | ±0.6 | ||

User calibration should refer to the industrial standard ISO8655-2.